Air Filter Replacement: Car Maintenance and Industrial Considerations

Air filters play a crucial role in maintaining the performance and longevity of vehicles and industrial machinery. By removing contaminants such as dust, pollen, and debris from the air intake, they ensure clean airflow to critical components, preventing damage and optimizing efficiency. For instance, consider a hypothetical scenario where an automobile’s air filter becomes clogged with dirt particles. As a result, the engine is deprived of sufficient oxygen supply, leading to decreased fuel combustion efficiency and increased emissions. This example highlights the importance of regular air filter replacement not only for individual vehicle owners but also for industries relying on heavy machinery.

In addition to its impact on vehicle performance, air filtration is equally vital in various industrial settings. Industries such as manufacturing plants, construction sites, and power generation facilities often have processes that generate large amounts of airborne pollutants like dust, smoke, or volatile organic compounds (VOCs). These pollutants can pose serious health risks to workers if not adequately managed. Therefore, proper maintenance of air filters is essential to ensure optimal indoor air quality and protect employees’ well-being. Moreover, efficient removal of contaminants through frequent filter replacements contributes to sustained productivity by minimizing equipment downtime caused by malfunctions or breakdowns due to poor air quality.

The Importance of Regular Air Filter Replacement

Clean and properly functioning air filters are crucial for maintaining the performance and longevity of both cars and industrial machinery. Neglecting regular air filter replacement can lead to a variety of issues, including reduced engine efficiency, increased fuel consumption, and potentially costly repairs. By understanding the importance of this simple maintenance task, individuals and businesses can ensure optimal operation and avoid unnecessary expenses.

To illustrate the significance of regular air filter replacement, consider the following hypothetical scenario: A car owner consistently neglects replacing their vehicle’s air filter over an extended period. As a result, dust particles accumulate in the engine compartment, restricting airflow and causing excessive strain on various components. This case study provides an example of how disregarding air filter maintenance can have detrimental effects on vehicle performance.

There are several key reasons why regular air filter replacement is essential:

- Improved Engine Efficiency: Clean air filters allow for adequate oxygen flow into the combustion chamber, enabling efficient fuel burning. This leads to improved engine performance and power output.

- Enhanced Fuel Economy: Clogged or dirty filters restrict airflow, which forces engines to work harder and consume more fuel. Regularly replacing air filters ensures optimal fuel economy by reducing unnecessary energy expenditure.

- Prevention of Engine Damage: Dust particles present in unfiltered air can cause abrasion on internal engine parts like cylinders and pistons. Replacing filters in a timely manner prevents such damage from occurring.

- Cost Savings: While it may seem tempting to postpone routine maintenance tasks like air filter replacement to save money in the short term, doing so often leads to larger repair bills down the line due to preventable wear-and-tear on vital engine components.

| Improved Engine Efficiency | Enhanced Fuel Economy | Prevention of Engine Damage | Cost Savings |

|---|---|---|---|

| Increased power output | Optimal fuel usage | Protection against abrasion | Avoiding future repair costs |

| Efficient combustion process | Reduced energy expenditure | Prolonged engine life |

Considering the benefits outlined above, it is clear that regular air filter replacement should not be overlooked. By maintaining clean and functional filters, individuals can optimize their vehicle’s performance, save money on fuel expenses, prevent engine damage, and extend the overall lifespan of their car or machinery.

In the subsequent section, we will explore various signs that indicate the need for air filter replacement in order to help identify when this crucial maintenance task is necessary.

Signs that Indicate the Need for Air Filter Replacement

Section: Common Consequences of Neglecting Air Filter Replacement

Imagine a scenario where an individual neglects to replace their car’s air filter for an extended period. Let’s call this person Alex. Over time, the accumulated dirt and debris clog the air filter, restricting airflow into the engine. As a result, several consequences arise that highlight the importance of regular air filter replacement.

Firstly, reduced engine performance is a significant consequence of neglected air filter maintenance. With restricted airflow, the engine struggles to receive the necessary amount of oxygen needed for combustion. This deficiency leads to decreased power output and acceleration capabilities in vehicles like Alex’s car. In extreme cases, it may even cause stalling or difficulty starting the engine altogether.

In addition to diminished performance, neglected air filters can also contribute to increased fuel consumption. When an air filter becomes excessively dirty and clogged, it creates a rich fuel-to-air ratio within the engine. To compensate for this imbalance, modern vehicles equipped with electronic fuel injection systems often increase fuel delivery, leading to higher fuel consumption rates per mile traveled. Consequently, ignoring air filter replacement not only affects vehicle performance but also causes unnecessary financial burden due to frequent refueling.

Apart from impacting individual vehicle owners’ experiences, disregarding air filter maintenance carries broader implications for environmental sustainability as well. A contaminated air filter allows particulate matter and other pollutants to bypass filtration mechanisms and enter the atmosphere through exhaust emissions. By increasing airborne pollution levels such as harmful gases and fine particles known as PM2.5 or PM10 (particulate matter smaller than 2.5 or 10 micrometers), these neglected filters contribute to deteriorating air quality detrimental to both human health and ecosystems alike.

Consider these unfortunate outcomes resulting from prolonged negligence:

- Decreased engine performance

- Increased fuel consumption

- Environmental pollution

- Financial strain

To further emphasize these consequences visually:

| Consequence | Description |

|---|---|

| Decreased engine performance | Restricted airflow leads to power loss and difficulty starting the engine. |

| Increased fuel consumption | Clogged air filters cause a rich fuel-to-air ratio, leading to higher fuel consumption rates. |

| Environmental pollution | Neglected filters allow pollutants to bypass filtration mechanisms, deteriorating air quality. |

| Financial strain | Frequent refueling due to decreased efficiency puts an additional burden on vehicle owners’ budgets. |

As we have seen, neglecting air filter replacement can result in adverse effects on both individual vehicles and the environment as a whole. Hence, it is crucial for car owners and industries alike to prioritize regular maintenance of their air filters.

Transitioning into our subsequent section about “Different Types of Air Filters for Cars and Industrial Applications,” let us explore how various types of air filters cater to specific needs within these domains without compromising effectiveness or performance.

Different Types of Air Filters for Cars and Industrial Applications

Imagine a scenario where you are driving your car on a hot summer day, feeling the breeze blowing through open windows. Suddenly, an unpleasant smell fills the air, making it difficult to breathe comfortably. This could be due to neglecting one crucial aspect of car maintenance – replacing the air filter regularly. In this section, we will explore the importance of regular air filter replacement in both car and industrial applications.

The Consequences of Neglect:

Neglecting or delaying air filter replacement can lead to several undesirable consequences. For instance, in cars, a clogged or dirty air filter restricts airflow into the engine, affecting its performance and fuel efficiency. Over time, this can increase wear and tear on engine components as they struggle to compensate for insufficient oxygen supply.

Similarly, in industrial settings such as manufacturing plants or construction sites, failing to replace air filters can have severe repercussions. Dust particles and contaminants that accumulate within these filters may escape into the surrounding environment if not adequately controlled. This can compromise indoor air quality, leading to health issues among workers while also negatively impacting machinery efficiency.

The Need for Regular Air Filter Replacement:

To better understand why regular air filter replacement is essential in various contexts, consider the following points:

- Improved Performance: A clean and well-maintained air filter allows for optimal airflow, ensuring efficient combustion in engines and enhancing overall system performance.

- Enhanced Fuel Efficiency: When an engine receives adequate amounts of clean air, it operates more efficiently by burning fuel effectively. As a result, it consumes less fuel per unit distance traveled.

- Prolonged Equipment Lifespan: Clean air free from contaminants helps minimize premature wear on critical components like pistons and valves. By reducing abrasive particles’ entry into sensitive areas, regular filter replacement contributes to extending equipment lifespan.

- Healthier Work Environment: In industrial settings where airborne pollutants are prevalent (e.g., dust, fumes, allergens), replacing air filters regularly is crucial for maintaining a safe and healthy work environment. It minimizes the risk of respiratory issues among employees while also ensuring compliance with occupational health standards.

Table: Air Filter Replacement Frequencies

| Application | Recommended Frequency |

|---|---|

| Cars | Every 12,000-15,000 miles or as per manufacturer’s guidelines |

| Industrial Processes | Varies depending on pollutant levels in the working environment |

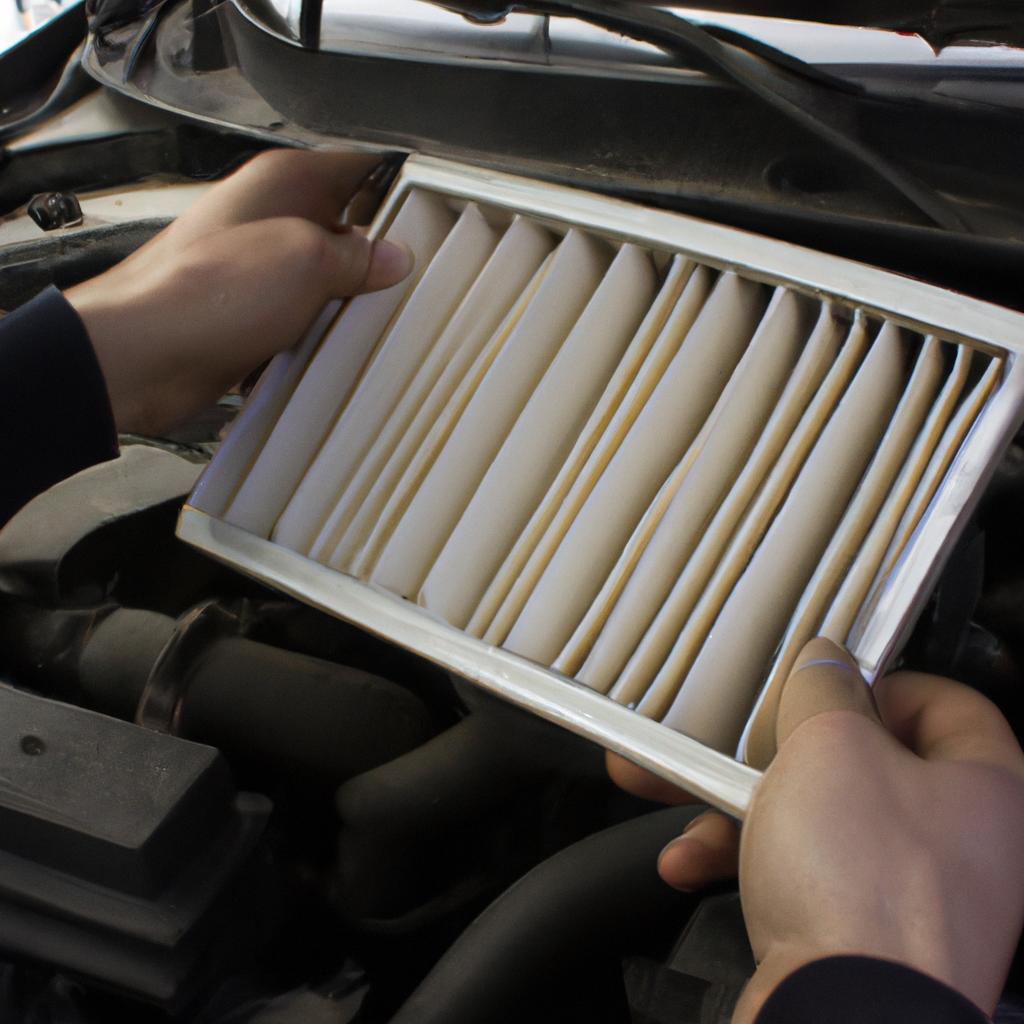

Proper Procedure for Replacing an Air Filter:

In the subsequent section, we will delve into the proper procedure for replacing an air filter without compromising its effectiveness or damaging other components. By following these steps diligently, you can ensure that your vehicle or industrial equipment operates optimally and maintains a clean and healthy environment.

Understanding the significance of regular air filter replacement allows us to now explore the proper procedures involved in replacing them effectively.

Proper Procedure for Replacing an Air Filter

Building upon our understanding of different types of air filters, it is crucial to recognize the significance of regular air filter replacement in both automotive and industrial settings. By examining a hypothetical scenario involving a car engine’s deteriorating performance due to an outdated air filter, we can gain insights into the potential consequences that could arise without proper maintenance.

Paragraph 1:

Imagine a situation where an individual neglects the recommended interval for replacing their car’s air filter. Over time, dust particles, debris, and pollutants accumulate within the filter, obstructing its ability to effectively trap contaminants. As a result, these impurities begin infiltrating the vehicle’s engine, affecting its efficiency and overall performance. Reduced airflow can lead to decreased fuel economy, diminished power output, and increased emissions – all of which significantly impact driving experience and environmental sustainability.

To emphasize the importance of regular air filter replacement further, consider some key factors that highlight its necessity:

- Enhanced Engine Longevity: A clogged or inefficiently functioning air filter places additional strain on vital engine components such as pistons and cylinders. With contaminants bypassing the compromised filtration system, abrasive particles accelerate wear-and-tear processes leading to premature engine failure.

- Improved Fuel Efficiency: When an air filter becomes saturated with dirt and other particulates, it restricts airflow necessary for optimal combustion. Consequently, fuel-air mixture imbalances occur within the engine resulting in suboptimal mileage per gallon.

- Environmental Responsibility: Outdated air filters contribute to heightened emission levels by allowing unfiltered pollutants into the atmosphere. Maintaining clean filters helps curb harmful emissions that adversely affect both human health and ecological balance.

- Cost Savings: Regularly replacing air filters prevents costly repairs caused by contaminated engines. By investing in routine maintenance practices like timely filter replacements, individuals can save significant amounts on potential repair bills down the line.

Paragraph 2:

To better illustrate the impact of regular air filter replacement, let us examine a comparison table showcasing the consequences of neglecting this crucial maintenance task.

| Consequence | Neglected Air Filter Replacement | Regular Air Filter Replacement |

|---|---|---|

| Engine Performance | Diminished power output | Consistent and optimized performance |

| Fuel Efficiency | Reduced mileage per gallon | Improved fuel economy |

| Environmental Impact | Increased emission levels | Decreased pollution |

| Maintenance Cost | Higher risk of engine repairs | Lower overall repair expenses |

As highlighted in the table, failing to replace air filters regularly can result in diminished engine performance, reduced fuel efficiency, increased environmental harm, and higher maintenance costs. These repercussions underline the criticality of adhering to recommended intervals for air filter replacements.

Transition into the subsequent section:

By recognizing the implications outlined above, it becomes evident that regular air filter replacement offers numerous benefits for both car owners and industrial operators alike. Let us now explore these advantages in more detail.

Benefits of Regular Air Filter Replacement

To understand the importance of regular air filter replacement, let us consider a hypothetical scenario involving two similar cars. Car A has diligently followed the proper procedure for replacing its air filter at recommended intervals, while Car B neglects this crucial maintenance task. Over time, both cars accumulate dirt and debris in their engines’ intake systems due to normal driving conditions.

Regular air filter replacement offers several benefits that go beyond ensuring optimal engine performance. These advantages can be summarized as follows:

- Improved Fuel Efficiency: By preventing clogged filters from obstructing airflow into the engine, clean air filters enable efficient combustion and reduce fuel consumption.

- Enhanced Engine Longevity: Clean air filters provide adequate protection against harmful contaminants such as dust, pollen, and debris that may otherwise cause premature wear on internal engine components.

- Lower Emissions: Properly functioning air filters help maintain ideal air-to-fuel ratios, resulting in reduced emissions of pollutants like carbon monoxide (CO) and nitrogen oxide (NOx).

- Sustained Overall Performance: Regularly replacing air filters ensures consistent engine power delivery and minimizes the risk of sudden breakdowns caused by restricted airflow.

Consider the following table showcasing comparisons between well-maintained vehicles with regularly replaced air filters and those without proper filtration upkeep:

| Well-Maintained Vehicle | Neglected Maintenance | |

|---|---|---|

| Mileage | Consistently higher mileage per gallon | Gradual decrease in fuel efficiency |

| Durability | Sustains engine longevity | Increased likelihood of mechanical issues |

| Environment | Reduced emissions | Higher pollution levels |

| Reliability | Reliable performance | Elevated risks of unexpected breakdowns |

In conclusion, maintaining a strict schedule for regular air filter replacement is essential for optimizing vehicle performance, increasing durability, reducing emissions, and enhancing reliability. Neglecting this vital maintenance task can lead to reduced fuel efficiency, engine damage, increased emissions, and a higher likelihood of unexpected breakdowns.

Moving forward, let us explore considerations for choosing the right air filter for industrial applications as we delve into the next section.

Considerations for Choosing the Right Air Filter for Industrial Applications

Having discussed the benefits of regular air filter replacement in automotive settings, it is equally important to understand the considerations involved in selecting the right air filter for industrial applications. The demands and challenges faced by industries vary greatly from those encountered in cars, necessitating careful evaluation of factors such as filtration efficiency, particle size retention, airflow capacity, and service life.

Example:

To illustrate these considerations, let us consider a hypothetical scenario where a manufacturing facility operates heavy machinery that generates high levels of airborne contaminants. In this case, choosing an appropriate air filter becomes crucial not only for maintaining indoor air quality but also for safeguarding the health and safety of workers.

Considerations when choosing an air filter for industrial applications include:

-

Filtration Efficiency:

- High-efficiency filters are essential in environments with strict contamination control requirements.

- Filters should be capable of removing both fine particles (such as dust) and larger ones (like debris or lint).

-

Particle Size Retention:

- Understanding the size distribution of contaminants is vital to select filters that can effectively capture them.

- Different types of filters have varying capabilities in retaining specific particle sizes.

-

Airflow Capacity:

- Industries often require adequate airflow rates to maintain proper ventilation systems and equipment performance.

- It is essential to choose filters that allow sufficient airflow while still capturing contaminants effectively.

-

Service Life:

- Considering the cost-effectiveness aspect, longer-lasting filters may be preferred if they do not compromise filtration efficiency.

- Balancing longevity with efficacy ensures optimal performance over time without frequent replacements.

Table: Comparison of Air Filter Types

| Air Filter Type | Filtration Efficiency | Particle Size Retention | Airflow Capacity |

|---|---|---|---|

| Fiberglass | Moderate | Small particles | High |

| Pleated | High | Wide range of sizes | Moderate to high |

| HEPA | Very high | Ultrafine particles | Low to moderate |

| Activated Carbon | Variable | Odor and gas removal | Low |

In industrial settings, choosing the right air filter is crucial for maintaining a clean and safe working environment. By considering factors such as filtration efficiency, particle size retention, airflow capacity, and service life, industries can ensure optimal performance while effectively controlling airborne contaminants.

Note: It is important to evaluate specific requirements and consult with industry professionals when selecting air filters for industrial applications in order to make informed decisions that align with individual needs and regulations.

Comments are closed.